How to make 10000 manufacturers comply with Schedule M

- Ganadhish Kamat

- Ganadhish KamatBackground -

Government of India amended the Drugs Rules 1945 on 28th December 2023 vide GSR 922(e) to revise the Schedule M. While the revised document has lot of flaws (as mentioned in my earlier blog) it is significant improvement over the existing document and if implemented correctly by all manufacturers, will result in significant improvement in the Quality of drugs in India. The revised Schedule M comes in effect from 28th June 2024 for large manufacturers (Turnover >250 crore) and from 28th December 2024 for small and medium scale manufacturers (Turnover <250 crore). The revised Schedule M is based on WHO TRS 986 published in 2014. So hopefully the manufacturers who are exporting their products and inspected by WHO must be already complying to revised rules. The question remains of other manufacturers who exclusively make products for distribution in India.

Challenges in compliance -

While revision of the Schedule M is the first step of improving compliance in Indian pharma industry, the big question is how will CDSCO ensure compliance to revised schedule M in reasonable period of time due to following challenges.

- Absence of culture of self-compliance - Ideally the responsibility of the compliance to Drug laws and the Rules lies with the manufacturers. As the draft was published in 2018, there was enough time for manufacturers to take proactive measures to comply with the rules. However from the representations being made to government by various associations for delaying implementation, it appears that the culture of compliance is missing and enforcement is the only way.

- Large number of manufacturers - There are more than 10,000 manufacturers in the country. Most of these are small and medium scale manufacturers only catering to domestic market. Since there are significant changes in the requirements a thorough inspection (at least 5 days with 2 inspectors) will be required to verify the compliance. This will require significant resources and time. Last year CDSCO conducted around 300 risk based inspections. At that rate it will take > 30 years to cover all the manufacturers. Obviously CDSCO alone can't complete this task on its own and major lifting will have to be done by the state regulatory agencies.

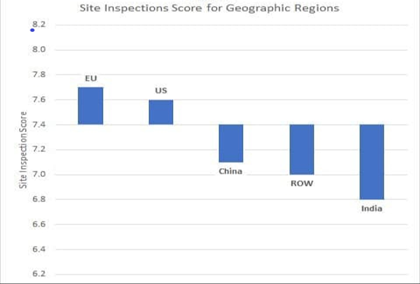

- Ineffectiveness of inspection by state regulatory agencies - The risk base inspections carried out by CDSCO jointly with state agencies revealed that approximately 36% of the manufacturers had serious non-compliances with old Schedule M and had to be shut down. This is in spite of the fact that these manufacturers were regularly (once a year) inspected by respective state regulatory agencies. This indicate ineffectiveness of inspection by state agencies in ensuring compliance. The reasons for this need to be identified and addressed.

- One of the main reasons could be inadequate number of inspectors commensurate with the workload. While the accurate number of inspectors is not available from authentic government sources, from various open sources I could determine that at Center and State level put together, currently there are around 1300 Drug inspectors in the country. Apart from inspecting 10,000 manufacturing units, they also have to inspect around 500,000 drug stores. Some of the state inspectors also have responsibility of inspecting food outlets. Such work load for only 1300 inspectors is very high to perform thorough inspections. Currently the duration of inspections by state regulators is around 1 - 2 days with 1 or two inspectors. In comparison to this, USFDA inspections lasts for 1 - 2 weeks with 1 - 2 inspectors. Considering this glaring difference, it is not surprising that USFDA inspections are able to discover large number of serious non-compliances where as Indian state FDA inspections rarely detect any major violations.

- Another reason could be lack of training & auditing skills. A good inspector should have thorough understanding of systems and processes followed in the industry apart from the knowing the laws. While the inspectors are familiar with the regulations, many of them have no or limited industry experience. Specifically they have no experience with various software used in industry such as ERP systems, Electronic records, LIMS, Chromatography software etc. This limits their ability to review electronic data and audit trails to detect any data manipulations. They also do not have strong product / process understanding which limits their ability to detect flaws in design of systems, processes, specifications, methods, qualifications, validations, investigations etc.

Suggestions for achieving compliance -

As mentioned earlier, technically the onus of compliance lies with the manufacturers. But considering the inadequacies in the inspection system and lack of tough repercussions of failure in regulatory inspections, there is possibility that manufacturers may take a chance of getting through the inspection without full compliance. To address this following actions may be considered.

- Self assessment - CDSCO should create an elaborate self assessment questionnaire for the manufacturers. The manufacturers should be made to complete the document providing explanations or document numbers etc to demonstrate compliance. They should also be made to get it certified by an independent consultant (USFDA uses this approach in case of Warning letters). Manufacturers should be made to submit the completed questionnaire along with an affidavit that they have done comprehensive assessment and fully comply with the rules prior to the effective dates mentioned above.

- Deterrent - A strong deterrent needs to be created for failure to comply with the rules to prevent deliberate violations and negligence. Inspection process should categorize the non-compliances as Critical, Major and Others in line with PICS guidelines. A critical violation or more than 6 Major violations should result in facility being classified as non-compliant. Such situation should result in not only suspension of the license but also recall of all the distributed drugs manufactured using non-compliant facility. This will also act as strong deterrent for the companies who get their products manufactured on loan licence or on B2B basis. They will have to ensure that their contract manufacturers or suppliers comply with the requirement to avoid risk of recall of their products. Restarting of such facility should only be allowed after all deficiencies have been corrected and verified in re-inspection. Government should clearly communicate the implications of running the operations with non-compliance to revised schedule M beyond the effective date to the manufacturers so that incase for any reason they are not able to fully comply by the date, they stop the operations voluntarily instead of risking enforcement actions.

- Leveraging inspections by other agencies - Manufacturers should be compelled to submit inspection reports from other agencies within 3 days. Serious violations such as data manipulations and other fraudulent actions if identified in such inspection should result in actions mentioned above.

- Improving inspection process of state regulators - All the inspectors in state regulatory agencies have to be trained in revised rules and inspection techniques including verification of electronic data and audit trails. It might be good idea to send them for industry orientation for a week or two especially to learn electronic data management and product development aspects. CDSCO and the State regulatory agencies should engage retired quality professionals to train the inspectors. The inspection process should be standardized so that all the major systems are covered. The duration of inspection should be increased to minimum 5 days. Inspection team should include one System expert and one QC expert. A microbiologist should be added in case of sterile facilities. Use of checklist may help in ensuring that major aspects are not missed during inspection. CDSCO along with state agencies should do realistic assessment of resources required to complete the inspections of all the manufacturers in respective state within one year of implementation date. Considering inspection time, travel time, report writing and review of response minimum 15-20 working days will be required per site. Considering 10,000 sites, around 800 inspectors will be required for this activity alone.

- Accountability of state regulators - While it is true that the inspections are based on sample checks and may not detect all the violations, failure to detect significant gap such as non-existent controls or systems or necessary equipment etc is not acceptable. Some kind of recognition and retribution system needs to be created to encourage thoroughness in inspection and discourage dereliction.

- Training - Training on new schedule M is being conducted by CDSCO and various associations such as IDMA, ISPE, AIPAC etc. These training programs are largely focused on explaining what's new in the revised rules. This information can be also gathered by reading the rules. More focused training is required on how to comply with certain new requirements such as PQS, APQR, QbD, Life cycle management approach of validation, change management etc. While all of us were preparing for compliance to USFDA regulations, one of the great source of information for continued learning was FDA 483s and warning letters issued to other companies. USFDA publishes all warning letters on their website and makes inspectional observations (483s) available through FOI. If more than 10 FOI requests are received for specific 483, FDA makes it available on their website. FDA also publishes annual summary of 483 observations which provides good insights to industry on FDA's focus and improvement areas. It will be of great help to MSMEs if similar system is adopted by Indian regulatory agencies. To begin with, CDSCO can make inspection reports of risk based inspections conducted last year available on their website. Consulting firms like McKinsey or BCG can be roped in to do data analysis and provide summary for benefit of all manufacturers. I am sure they will be willing to do it as Pro bono activity. The training program can then be tailored to address major deficiencies using Pareto principle.

Conclusion -

Ensuring that all the manufacturers are complying with the Schedule M is not an easy task especially considering various challenges mentioned earlier. Government agencies will have to plan for the necessary resources to accomplish the task of inspecting all the sites within reasonable period of time and take various actions suggested to achieve the end goal. With limited resources and the available expertise, it may be difficult for government agencies to achieve the task on their own and they should not hesitate to seek help from retired industry experts. I am sure that they will be more than willing to help because improved compliance and the quality of drugs will help entire country.

Good idea.I volenter for inspection of 5 industry

ReplyDeleteThis is high time to make our manufacturing unit in compliance.

ReplyDeleteReally good thought, I seen most of regulatory inspectors of FDA, or other agencies are having full enthusiasm to learn and do something to their country, but I didn’t see in our system.

ReplyDeleteVery apt analysis of Indian regulators current inspection challenges and solutions for the same

ReplyDeleteTrue story and needs joint working of manufacturers and FDA / CDSCO to establish M Schedule compliance and quality consistency

ReplyDelete